TECHNICAL EXECUTION OF THE CONTINUOUS FLIGHT AUGER PILE

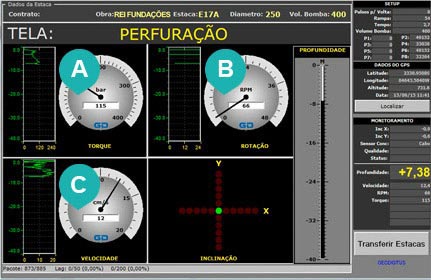

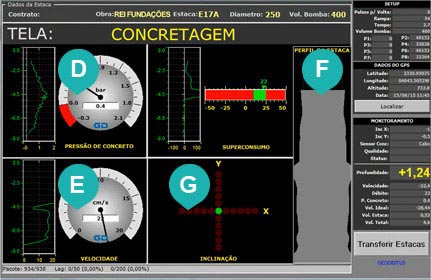

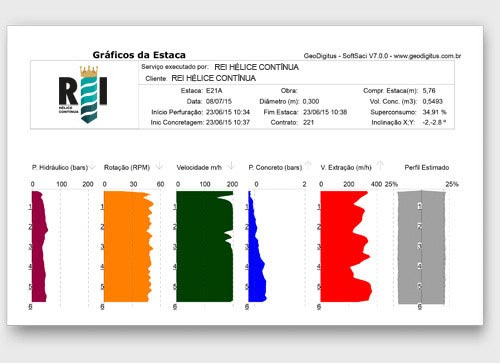

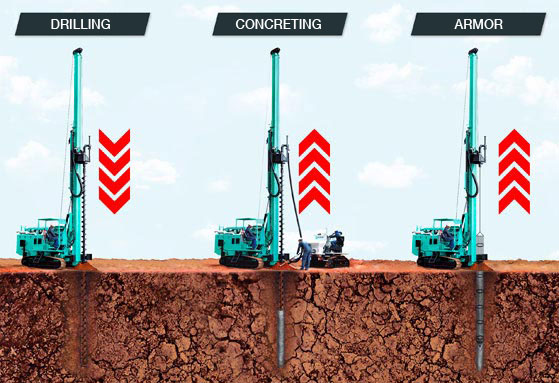

In the foundation works made by monitored mini continuous flight auger (Mini CFA), we highlight three distinct steps of the technical execution process, which are:

The monitored continuous flight auger pile is drilled with a spiral auger and is driven into the ground by rotation. The spiral augers are filled with the ground, and at the bottom of the auger there are knives to facilitate the cutting of high-resistance grounds, which can cut through 30 to 60 *SPT soil layers depending on the type of material.

Examples of soil types: silt, clay, sand, etc.

The machine achieves the required depth in each project with high productivity, which varies between 250 and 600 meters per day, depending on the diameter of the propeller, the foundation depth of the pile and the type of ground.

At the end of the drilling process, the concreting of the pile is started. In the spiral auger there is a hollow central pipe through which the concrete is pumped and as the auger is extracted from the ground, it is simultaneously filled with pressurized pumped concrete (being controlled by the drill operator), so that no failures or bubbles occur in the *stem.

A specific concrete type is used that follows the requirements of the Brazilian Association of Technical Standards (ABNT) NBR 6122: 2010 (Item F.9) that are:

- Cement consumption of not less than 400 kg/m³;

- *Slump test equal to 22±3, according to ABNT NBR NM 67;

- Water–cement ratio ≤ 0,6;

- Agglomerate: sand and gravel (Gravel 0);

- % of mortar mass ≥ 55%;

- Pumped type mixture;

- *Fck ≥ 20 *MPa at 28 days, according to ABNT NBR 6118, ABNT NBR 5738 and ABNT NBR 5739.

At the end of the concreting phase, the cage frame is placed and manually inserted into the pile or with the aid of a machine.

Long cages should be built with thick bars and spiral stirrups, while the tips should be tapered so that they do not screw into the drill wall.

Technical References:

*SPT: The standard penetration test (SPT) is an in-situ dynamic penetration test designed to provide information on the geotechnical engineering properties of soil.

*Stem: It is the base of the pile.

*FCK: It is a characteristic resistance of the concrete to compression.

*MPa: A megapascal is a measure of the compressive strength of concrete. (strength on the surface area).